Round Bars

Shree Arbuda Steel is a trusted exporter and supplier of high-quality Round Bars in various materials including Stainless Steel, Carbon Steel, and Alloy Steel. Our Stainless Steel Round Bars are popular for their corrosion resistance, durability, and excellent surface finish, making them ideal for marine, chemical, and architectural applications. Carbon Steel Round Bars offer high strength and are widely used in industrial machinery and automotive components. For critical engineering demands, our Alloy Steel Round Bars provide superior performance in high-temperature and high-pressure environments. We ensure precise dimensions, international quality standards, and prompt global delivery

Stainless Steel Round Bars

Carbon Steel Round Bars

Alloy Steel Round Bars

Stainless & Duplex Steel

| Range | 3.17 MM TO 350 MM DIA |

|---|---|

| Stainless Steel | (ASTM / ASME SA 276) TP 304, 304L, 309S, 309H, 310S, 316, 316L, 316 TI, 317, 321, 347, 410, 420, 430, 431, 440A, 440B, 440C, 446 |

| Stainless Steel | (ASTM / ASME SA 479) TP 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316H, 316L, 316 TI, 317, 321, 321H, 347, 347H, 410, 430, 431, 444 |

| Duplex Steel | (ASTM / ASME SA 276) UNS NO. S31803, S32205, S32550, S32750, S32760 |

Carbon & Alloy Steel

| Range | 1 MM TO 350 MM DIA |

|---|---|

| Stainless Steel | ASTM / ASME A 105 |

| Alloy Steel | ASTM / ASME A 182 GR F5, F9, F11, F12, F22, F91ASTM / ASME A 729 GR B11 & B22 |

Nickel & Copper

| Range | 3.17 MM TO 350 MM DIA |

|---|---|

| Product | Round Bars - Nickel Alloy |

| Specifications |

ASTM / ASME SB 160 UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201) ASTM / ASME SB 164 UNS 4400 (MONEL 400) ASTM / ASME SB 425 UNS 8825 (INCONEL 825) ASTM / ASME SB 166 UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601) ASTM / ASME SB 446 UNS 6625 (INCONEL 625) ASTM / ASME SB 574 UNS 10276 (HASTELLOY C 276) ASTM / ASME SB 472 UNS 8020 (ALLOY 20 / 20 CB 3) |

Hastelloy

| Grades | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000 |

|---|---|

| Type |

Hastelloy Round Bar Hastelloy Bright Bar Hastelloy Polish Bar Hastelloy Black Round Bar Hastelloy Forged Bar Hastelloy Forged Round Bar Hastelloy Hex Bar Hastelloy Forged Hex Bar Hastelloy Flat Bar Hastelloy Rod |

Inconel

| Grades | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 |

|---|---|

| Sizes | 1mm to 200mm diameter |

| Type | Bars, Rods, Wire |

| Standard | ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, NACE |

Incoloy

| Grades | Incoloy 800, Incoloy 825, Incoloy 925, Incoloy A-286, Incoloy DS |

|---|---|

| Standard | ASTM B408, AMS 5766, ISO 9723, ISO 9724, BS 3076NA15, BS 3075NA15, EN 10095, VdTÜV 412 & 434 |

| Type |

Round Bar, Bright Bar, Polish Bar, Black Round Bar, Forged Bar, Forged Round Bar, Hex Bar, Forged Hex Bar, Flat Bar, Rod |

Monel

| Grades | Monel 400, Monel K500 |

|---|---|

| Range | 5 mm dia to 500 mm dia in 100 mm to 6000 mm Length |

| Standard | ASTM / ASME SB 164 |

Nironics 50

| Features | Nitronic 50 Stainless Steel is an austenitic stainless steel offering a superior combination of strength and corrosion resistance compared to Stainless Steel 316, 316L, 317, and 317L. It has about double the yield strength at room temperature compared to 316/316L and 317/317L. It maintains good mechanical properties at both elevated and sub-zero temperatures. Nitronic 50 remains non-magnetic even when severely cold worked. It provides excellent corrosion resistance, especially in marine environments. Despite its strength, it can be fabricated using the same equipment and cooling techniques as Stainless Steel 300 series. |

|---|---|

| Grades Available | XM-19 (UNS S20910), Nitronic 50 Annealed, XM-19HS |

Nitronics 60

| Features | Nitronic 60 Stainless Steel is an austenitic alloy known for having the best galling resistance among all Stainless Steels. It boasts excellent pitting resistance, outstanding corrosion resistance, and good high-temperature properties at temperatures up to 982°C. It provides superior oxidation resistance and improved crevice corrosion and chloride pitting resistance compared to Stainless Steel 316. Nitronic 60 can be easily formed using common techniques without the need for pre-heating, and can be welded using methods like gas metal arc, gas tungsten arc, and submerged arc. The alloy can be hardened by cold working. |

|---|---|

| Primary Elements |

- 16-18% Chromium - 8-9% Nickel - 7-9% Manganese - 3.5-4.5% Silicon - Balance Iron - Trace amounts of Carbon, Sulfur, Phosphorus, and Nitrogen |

| Industries Served |

- Oil and Gas Production - Hydroelectric Power - Petrochemical - Food Processing - Automotive - Zarine - Pharmaceutical - Construction - Chemical Sector |

Titanium

| Specifications | Titanium Round Bar |

|---|---|

| Grade | Gr1, Gr2, Gr3, Gr5, Gr7, Gr4, Ti-6AL4V ELI, Gr.9, Gr.12 |

| Standard | ASTM B348, ASTM F136, ASTM F67, AMS 4928 |

| Size | Diameter: 4mm to 350mm, Length: 50mm to 6000mm |

| Payment | T/T or L/C at sight |

| MOQ | 10 kg |

| Package | Ply Wooden Case or as requested |

| Delivery Time | 7 - 30 days after confirmation |

| Applications | Industry, Glasses, and more |

Tantalum

| Specifications | Tantalum Bar |

|---|---|

| Material | Tantalum Bar, Tantalum Tungsten Alloy Bar, Tantalum Alloy Rod |

| Grade | RO5200, RO5400, RO5252 (Ta-2.5W), RO5255 (Ta-10W) |

| Size | Dia 3mm to 120mm |

| Standard | ASTM B365-98 |

| Purity | >=99.95% or 99.99% |

| Material for Alloy Rod | RO5200, RO5400, RO5252 (Ta-2.5W) |

Specification of Stainless Steel Round Bar

| Specification | ASTM A276 / A479, ASME SA276 / A479 |

|---|---|

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | 14mm - 300mm |

| Thickness | 50 mm to 6000 mm Long |

| Length | 1 To 6 Meters, Custom Cut Length |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging |

Exporters of Round Bars Countries

| Saudi Arabia | Qatar | Canada | Bangladesh |

| Oman | UAE | Venezuela | Turkey |

| Kuwait | Africa | United Kingdom | Singapore |

| Netherlands | China | Malaysia | Sri Lanka |

Product Range

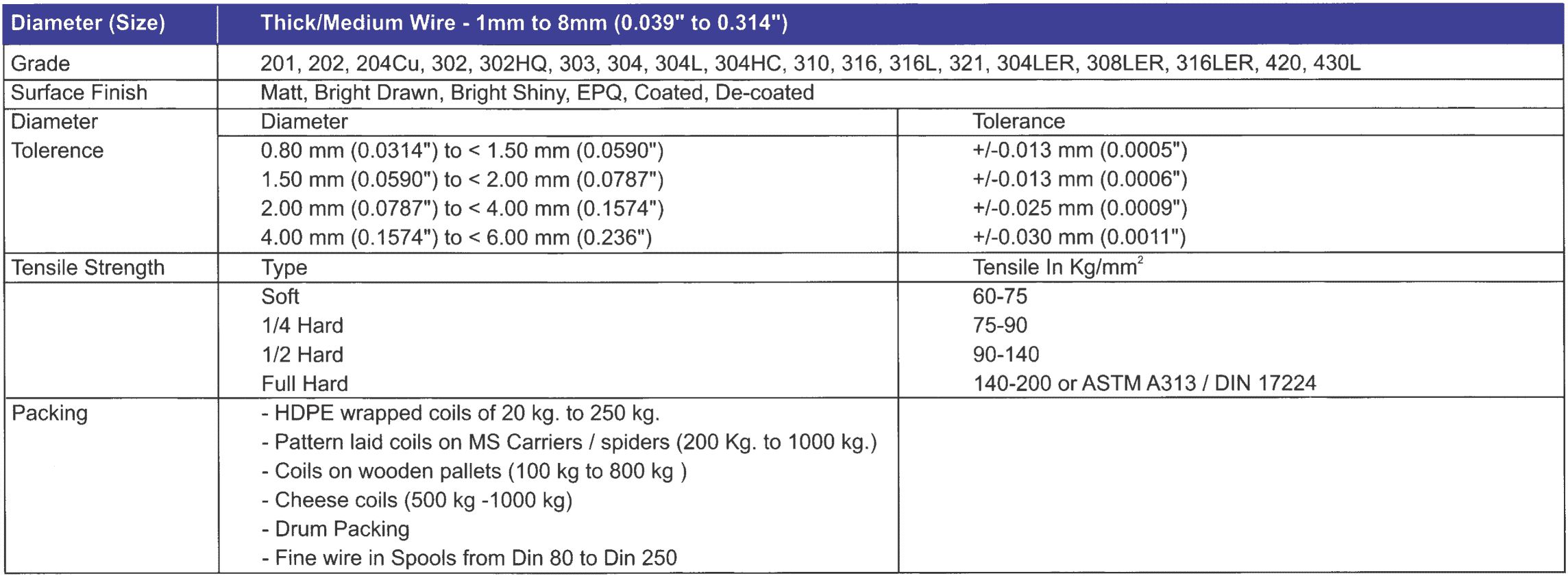

SS Wires Chart

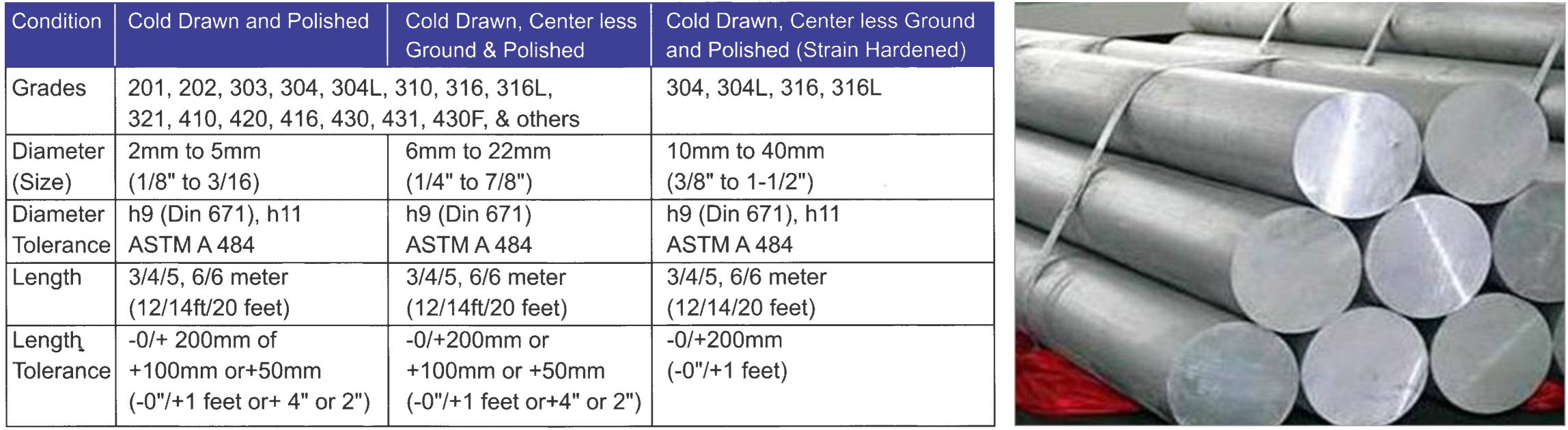

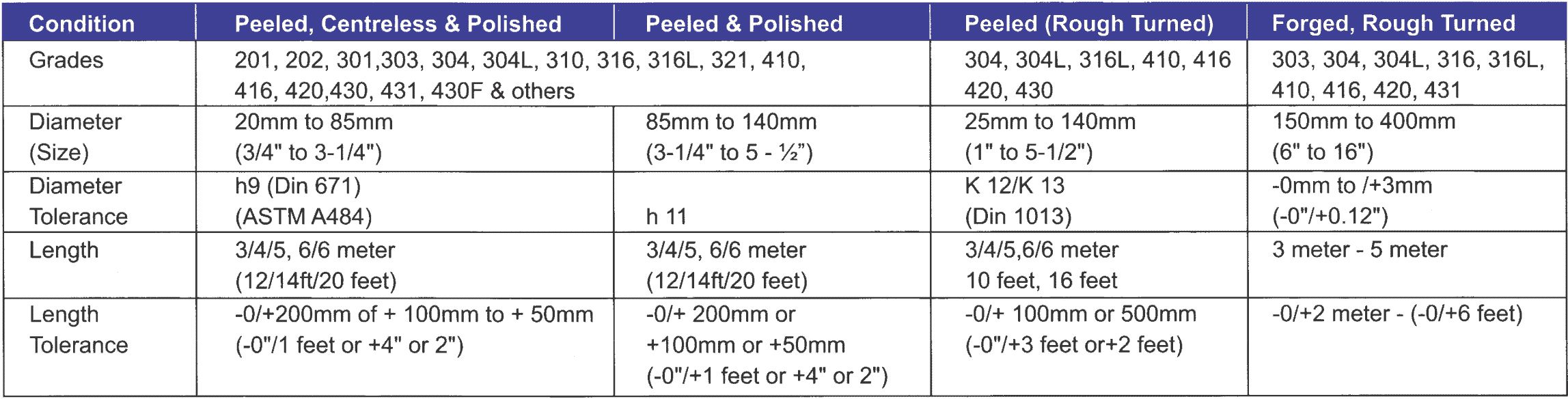

Stainless Steel Bright Bars Cold Drawn